Cadmium telluride solar cells use low cost manufacturing technology to produce low cost cells.

Cadmium telluride solar panels cost.

Cadmium telluride is a direct band gap material with high absorption for the full spectrum.

A main concern with cdte panels is pollution.

Excellent low light effect it works even indoor.

The temperature coefficient of cdte thin film solar module is only about 0 21 k make it much more heat resistant than crystalline solar modules.

A research team from washington state university claims to have developed a new manufacturing process to produce cadmium telluride cdte pv panels that is 45 cheaper than current industry standards.

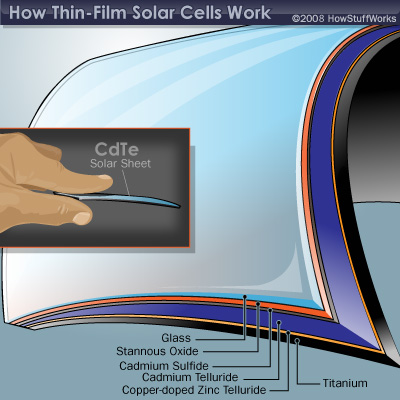

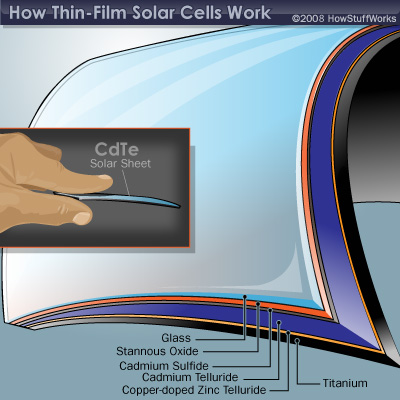

Production the most common cdte solar cells consist of a simple p n heterojunction structure containing a p doped cdte layer matched with an n doped cadmium sulfide cds layer which acts as a window layer.

Success of cadmium telluride pv has been due to the low cost achievable with the cdte technology made possible by combining adequate efficiency with lower module area costs.

Advancements in solar technology and the rapidly expanding landscape of photovoltaic arrays are raising concerns about environmental toxicity namely the use of cadmium telluride cdte in most photovoltaic pv solar cells.

Cadmium by itself is one of the most toxic materials known and cadmium telluride also has some toxic properties.

Direct manufacturing cost for cdte pv modules reached 0 57 per watt in 2013 and capital cost per new watt of capacity is near 0 9 per watt including land and buildings.

Additionally cadmium telluride panels can be manufactured at low costs as cadmium is abundant and generated as a byproduct of important industrial materials like zinc.